First Steps of A New Project

I thoroughly enjoy the initial steps of a new project. I’m talking about the steps after the design phase (assuming there is a design) when you go into the shop and start looking at the wood and breaking down stock. Joinery is nice and dry fitting things together is really satisfying, but these initial steps where you go from some rough sawn boards into approximately sized parts that each have an assigned purpose is exciting. This is where the project goes from theory to reality real quick. It is where you start thinking about color and grain match and best yield of the lumber on hand. I did a video a while back on how I use SketchUp to help me layout my cuts in this initial stage of a build. I do the same thing today and it has been really useful with a project I am just starting now: my flywheel lathe. This time I’m not deciding what lumber to buy, but how to work with what I already have.

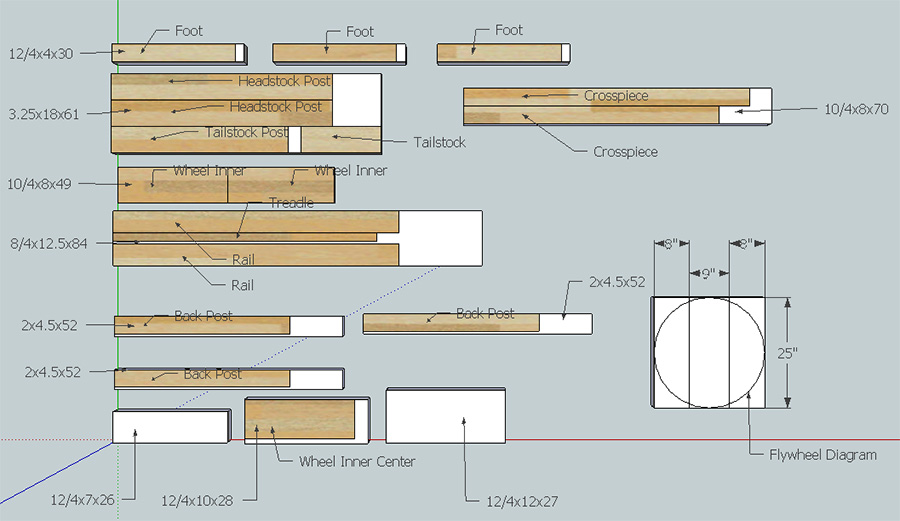

You see I have been mulling over this design for a few years now and acquiring lumber for it for just as long. It is a shop project so I haven’t been too concerned about color match or even having all the same species so I’m comfortable buying the lumber piecemeal. This is especially important considering the volume of lumber and thicker cuts that I need for this project. It definitely saves the burden on my wallet to buy over time opportunistically as I find pieces I need. This does make the cut planning process a little more involved and this is where SketchUp saves the day. Now I can create each of my boards and layout my pieces virtually to get the best yield. I have played around with various cut list plugins and I just find that I enjoy doing the process myself and I get a better yield in the long run and an even better grain match (though I’m not worried about that here) Because I have quite a few boards all in different sizes it is much easier to organize my thoughts on this virtual palette.

When I’m happy and convinced that I can get the parts I need from what I have, I can print out my SketchUp model and head to the shop to begin breaking down the stock into rough sizes. Then I can start planing everything to final size. I think this stage is where you truly begin to grasp the enormous potential of the raw lumber and how you as the woodworker can harness it and make it your own. It is a feeling that is at the heart of why we are woodworkers.