The Merits of Winging It

The internet is awesome. You can find just about anything in seconds and learn new things all the time. Woodworking has greatly benefited from this as we now have a place to share techniques that may have been lost over the generations. When you start a new project, or buy a new (or new to you) tool, you have an enormous body of knowledge to draw from. This is great but I think it has a dark side too. When was the last time you just gave something a shot without looking up how to do it? What happens when you can’t find the answer you are looking for? At some point you need to wing it and try to figure out the answer on your own. It can be frustrating but I can’t imagine a more rewarding experience.

My Frame Saw Experiment

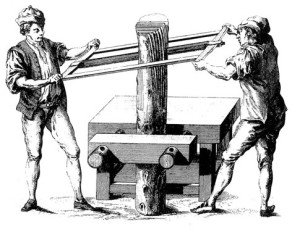

About 6 months ago I built a frame saw based on the now famous Roubo Saw pictured in a plate of two Frenchmen sawing veneer. I admit freely that I undertook this project because there was some great documentation online about how to build it. There is not however anything about how to actually use it. There are only a few people who have actually built one of these to begin with and there is only minimal conversation about how well it works or how it doesn’t work. So over the last six months I have been winging it when learning how to saw with any accuracy using this very different saw. Sharpening the massive 48″ blade was pretty elementary but setting it was a different story and with such a long blade length, getting it to run true took a fair amount of tinkering. I had to get behind the saw and cut up some boards making small adjustments to stance, grip, sometimes the teeth, how the work is held, etc before I could get consistent results from the saw. I have butchered a lot of wood, uttered a few colorful phrases, and more than once walked away from the saw in frustration.

About 6 months ago I built a frame saw based on the now famous Roubo Saw pictured in a plate of two Frenchmen sawing veneer. I admit freely that I undertook this project because there was some great documentation online about how to build it. There is not however anything about how to actually use it. There are only a few people who have actually built one of these to begin with and there is only minimal conversation about how well it works or how it doesn’t work. So over the last six months I have been winging it when learning how to saw with any accuracy using this very different saw. Sharpening the massive 48″ blade was pretty elementary but setting it was a different story and with such a long blade length, getting it to run true took a fair amount of tinkering. I had to get behind the saw and cut up some boards making small adjustments to stance, grip, sometimes the teeth, how the work is held, etc before I could get consistent results from the saw. I have butchered a lot of wood, uttered a few colorful phrases, and more than once walked away from the saw in frustration.

I can’t remember when I have had more fun!

This weekend, I sawed a 16/4 piece of 10″ wide Walnut in half without any deviation, then proceeded to slice off a 3/16″ piece of veneer from a 4/4 Quilted Maple board. I didn’t read how to do it online or in a book but figured it out on my own by “winging it”. I can honestly say I have learned more about how a saw works and efficiency during this period of time than any technique I picked up by watching a video or reading an article. We are all guilty of relying on other sources to help us and there is nothing wrong with asking questions and doing research. I’m going to keep doing it. But just like a 6″ jointer will never be wide enough, eventually those sources will come up empty. Figuring stuff out on your own can be tough, but in the end you feel invincible.

This weekend, I sawed a 16/4 piece of 10″ wide Walnut in half without any deviation, then proceeded to slice off a 3/16″ piece of veneer from a 4/4 Quilted Maple board. I didn’t read how to do it online or in a book but figured it out on my own by “winging it”. I can honestly say I have learned more about how a saw works and efficiency during this period of time than any technique I picked up by watching a video or reading an article. We are all guilty of relying on other sources to help us and there is nothing wrong with asking questions and doing research. I’m going to keep doing it. But just like a 6″ jointer will never be wide enough, eventually those sources will come up empty. Figuring stuff out on your own can be tough, but in the end you feel invincible.

I think I’ll go try to saw off a 1/16 thick piece of veneer from a 24″ wide piece of Lignum Vitae. That ought to knock me down a few pegs and even it out.

**Shameless Marketing Alert**

I’m publishing a lesson in The Hand Tool School this week on resawing and building this saw that is the direct result of this winging it. Maybe someone else can benefit from my trial and error.

Your Turn

When have you had to “wing it”? What happened and what did you learn?