Perspectives of an Amateur Woodworker From Inside the Professional Lumber Business

I think that it has become common knowledge these days after I trumpeted the news of my new job around the net but just in case, I took a job as the Director of Marketing for a Lumber Company. The J. Gibson McIlvain Co has been supplying our nation with quality hardwoods for more than 200 years. I still feel a bit like a kid in a candy store and if you pay any attention to my Twitter stream during an average week, you will find me snapping pics of huge stacks of lumber and getting drool all over the merchandise. I’m drawing to the end of my second month here and wanted to take a moment to reflect on some of the things I have learned. I’m one of the only furniture makers here. There are lots of “handy” guys that work here that do a lot of DIY stuff but really stick to 2x4s, dry wall, and decking. My boss is a fine furniture lover but that is about as close as any one gets to fine woodworker. The staff is extremely knowledgeable about wood and all of the various species that we distribute: how it machines, seasons, and what applications in which it excels, but I remain the only guy who looks at a piece of wide Mahogany and sees a glorious table top or solid board case side. I think a lot of this comes from the fact that we are a wholesale distributor and are a few paces removed from the lumber yards where we all go and buy our materials.

I think that it has become common knowledge these days after I trumpeted the news of my new job around the net but just in case, I took a job as the Director of Marketing for a Lumber Company. The J. Gibson McIlvain Co has been supplying our nation with quality hardwoods for more than 200 years. I still feel a bit like a kid in a candy store and if you pay any attention to my Twitter stream during an average week, you will find me snapping pics of huge stacks of lumber and getting drool all over the merchandise. I’m drawing to the end of my second month here and wanted to take a moment to reflect on some of the things I have learned. I’m one of the only furniture makers here. There are lots of “handy” guys that work here that do a lot of DIY stuff but really stick to 2x4s, dry wall, and decking. My boss is a fine furniture lover but that is about as close as any one gets to fine woodworker. The staff is extremely knowledgeable about wood and all of the various species that we distribute: how it machines, seasons, and what applications in which it excels, but I remain the only guy who looks at a piece of wide Mahogany and sees a glorious table top or solid board case side. I think a lot of this comes from the fact that we are a wholesale distributor and are a few paces removed from the lumber yards where we all go and buy our materials.

My goals here are to open up the company to some new markets and help us penetrate further into our existing markets. I have spent a lot of time working to understand who our customers are and how they buy and it is really exciting to see such a demand still today for beautiful hardwood in applications as diverse as yacht building to luxury homes. From the furniture builder’s perspective it is still shocking to me the volumes of some of the orders we fulfill. Tens of Thousands of board feet per order is highly common and it sounds impressive, but when you pair ten thousand board feet with African Mahogany, Walnut, Teak, or Ipe, you begin to grasp the size of the investment a window and door company, yacht builder, or flooring manufacturer makes on a regular basis.

More shocking (and refreshing) is the quality demanded by our customers. Only consistent color and straight grain will work. The prized “defects” that the furniture maker seeks are considered poor quality and are immediately cast aside when we receive the boards direct from mills all over the world. It is a major paradigm shift for me as I see a piece of figured Sapele and get really excited and our graders give me a funny look and say, “what are you, nuts? This stuff is going on the burn pile.”

The infamous burn pile has become my new call to arms as I am constantly working to save pieces from it to be marketed to a different set of customers: mainly people like me, the little guys. It should come as no surprise to those of use that shop for lumber in quantities of hundreds of board feet or less that we are a small minority of the sales that go on in the lumber industry in terms of board footage. Many of our clients buy more board feet in a month than I will ever use in my lifetime. These are the customers whose needs most readily need to get met and why wholesalers exist. So in an effort to fill these orders the industry has adopted grading and ordering paradigms that leave the small guy standing slack jawed in amazement.

Paradigm #1:

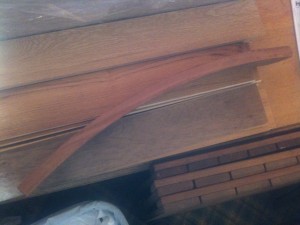

Figured wood is a defect. I found this piece of Ipe in a stack right off one of our trucks from the port. The furniture maker in me thinks I could really highlight that figure and do something cool with it like a panel to a door. I showed it to our buyer and she responded with, “eew, that is terrible Ipe, where did you find that?” and immediately scurried off to inspect the load and see which mill was sending us substandard lumber so a claim could be filed. You see in the decking world, you only want straight grain and identical color or your deck looks mottled and terrible. Straight grain and quartersawn pieces will be more stable or at least react predictably whereas all bets are off for the figured stuff.

Paradigm #2

Wide lumber isn’t really anything over 12″ wide. Personally I am excited when I find a 10″ wide board. Many of our customers are looking for 24″ and wider so it is common to see 30″+ stuff coming through the yard. The genuine Mahogany pictured here is 32″ and 36″ wide! The thing is other than the yacht manufacturers who are looking for wide cover boards, many people will buy this wide stuff and then rip it into thinner parts. The wide stuff gives them a lot of flexibility to choose grain and/or make wider panels for doors. I beginning to learn that it is not that the wide stuff is harder to come by, it is that it has already been sold to large manufacturers. These orders are very high dollar so are not made as often. However sourcing this stuff can take a very long time, especially the exotics so “just in time” is a relative term. As a distributor, if we miss an order our wide stock can sit for 6 to 8 months before another one comes around. I wonder if individual woodworkers would be interested in buying this crazy wide stuff board by board. I think I would.

Wide lumber isn’t really anything over 12″ wide. Personally I am excited when I find a 10″ wide board. Many of our customers are looking for 24″ and wider so it is common to see 30″+ stuff coming through the yard. The genuine Mahogany pictured here is 32″ and 36″ wide! The thing is other than the yacht manufacturers who are looking for wide cover boards, many people will buy this wide stuff and then rip it into thinner parts. The wide stuff gives them a lot of flexibility to choose grain and/or make wider panels for doors. I beginning to learn that it is not that the wide stuff is harder to come by, it is that it has already been sold to large manufacturers. These orders are very high dollar so are not made as often. However sourcing this stuff can take a very long time, especially the exotics so “just in time” is a relative term. As a distributor, if we miss an order our wide stock can sit for 6 to 8 months before another one comes around. I wonder if individual woodworkers would be interested in buying this crazy wide stuff board by board. I think I would.

Paradigm #3

Long is another relative term. If you have been to a good lumber yard you will find many 10 and 12 foot boards in the racks. Most of us tend to think in terms of 8 foot and less, and anything longer gets really hard to handle and most furniture can be made in 36″ or less. The first time I saw a 35 foot long board, I about wet myself. When you are building the deck of the next sailboat or yacht to come out of your factory, you want nice long boards to run the entire length. This idea also works the other way too. When our lumber graders are inspecting wood right off the trucks, the ends are often sawn off to control any checking that may have develped during shipment. Many times the boards must also be cut to a specific size. We end up with a lot of cut offs in the 2-4 foot range and often they end up in that burn pile again. Don’t cry, I’m rescuing them and setting them aside to be sold sometime in the future.

Paradigm #4

Wood moves, we all know that, but if there is any significant movement evident when the boards arrive at our yard, the piece is discarded as a defect. We woodworkers are used to jointing and planing every board to get it flat and will never trust that lumber yard wood is flat enough for our needs. A flooring company doesn’t have time for all that and will buy pre-dimensioned lumber that is already molded for install. Any bowing across a long board will flatten out once it is installed so no that is not a concern. Twist and cupping however are harder to correct so the boards exhibiting a penchant for this will be set aside as not meeting the grade. That same thing applies to staining from water, kiln stickers, minerals, or fungus (spalting). Even though most of this will plane away or adds character to the board that we like to highlight, these pieces will not meet the grade and be added to the “off” lists.

So you can imagine with all of these very very high standards, the stuff that we do sell is outstanding wood. I know that my employer does pride itself on really nice quality, but I have been dumbfounded by what I have seen. Our African Mahogany has changed my opinion on the stuff. Previously I never wanted to touch the stuff, but now I’m realzing that I just haven’t been buying very good quality. Unfortunately, it may be safe to say that for us smaller order guys, we are getting what is left over after the big guys have culled the pack of several thousand board feet.

No worries, though, we furniture making guys are a friendly and accepting bunch and even the “defects” make beautiful furniture. Don’t get me wrong, we (and other companies like us) sell plenty of top quality wood to your local lumber yard and you can still get really nice stuff. These yards however still have to buy smaller amounts of many different species so when compared to the window company that may buy nothing but Sapele in an order, you may still see some of that really consistent, straight grained stuff, disappearing.

I don’t think there is really anything to be done about this, it is just the way of the world and supply and demand. Personally I find it fascinating and I hope to be able to share more of these insights with you all…gotta go now a new truck is rolling down the hill full of what appears to be Cherry. I wonder what I can save for y’all from the burn pile.