Set Your Bevel to 59.333 Degrees

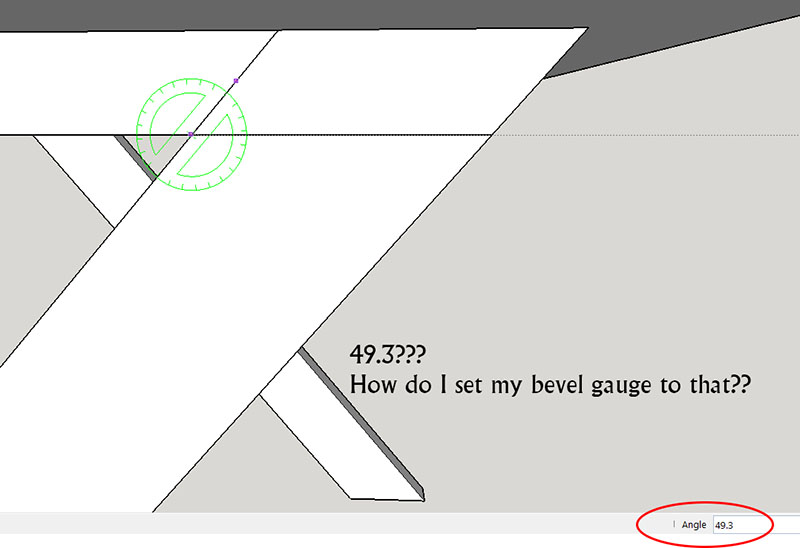

I was a music major so geometry was never my friend. So when I started tweaking the thickness of various parts on this dining table I’m building, my nice and neat 50 degree angles for the legs started to come apart. This is where I find I have trouble rendering my SketchUp model into real life. I can poke and prod the design all day long in virtual space to make it look pretty but when I shift to thinking about how I will actually make the piece this happens:

How the heck do I set my bevel gauge to 49.3?

More important, why would I want to do that. This angle is pretty tame, a lot of the time SketchUp spits out approximate numbers as in “~53.333”. Maybe you could make a case for an even .3 on some hyper accurate angle gauge or with one of those digital angle doohickey things, but I have a hand saw and a bevel gauge.

So out comes the pencil and straight edge and some cardboard so I can make a full sized drawing. This not only makes it super easy to capture these unknown angles with a bevel gauge, but it also makes the design more real. It may look great on the computer screen, but until I get it full size I can never quite tell how it will look and feel. Moreover, for something functional like a dining table it is hard to see how the piece will interact with the human body until you have something full size.

So out comes the pencil and straight edge and some cardboard so I can make a full sized drawing. This not only makes it super easy to capture these unknown angles with a bevel gauge, but it also makes the design more real. It may look great on the computer screen, but until I get it full size I can never quite tell how it will look and feel. Moreover, for something functional like a dining table it is hard to see how the piece will interact with the human body until you have something full size.

In this instance I was able to verify that the angle of this cross leg pattern was just right to allow someone with big feet like me to stretch out while sitting off the end of the table and be able to fit my feet through the space below the trestle where the legs cross. That is a nice bonus and one more variable that I can be certain about as I begin to actually start cutting joinery.

So how do you set your bevel gauge to 59.333 degrees? You don’t. Or at least you skip the numbers and just line up the gauge on your drawing.

Your Turn

When and why do you make full sized drawings of your furniture designs? Do you feel that too much virtual design work can lead to problems in the actual construction or is this just a sign that my virtual skills aren’t up to snuff?